Features and components of a coil cut to length machine

2023-10-17

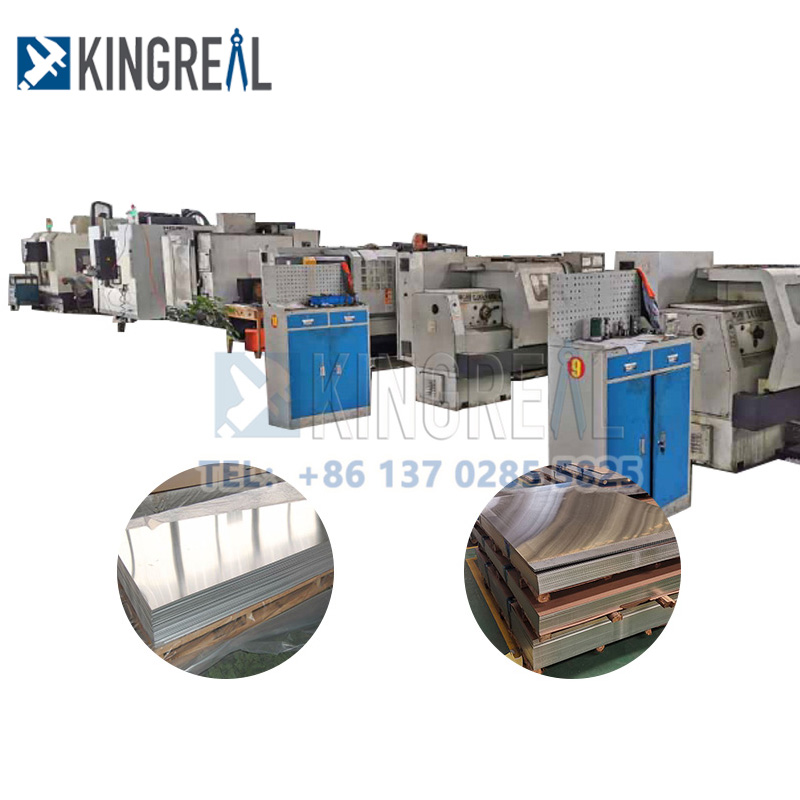

A coil cut to length machine is an industrial machine used to cut large coils of material, typically metal coils, into precise lengths. This type of machine is commonly used in industries such as steel processing, metal fabrication, and manufacturing where accurately cut pieces of material are needed for further processing or assembly.

Key features and components of a coil cut to length machine include:

1. Uncoiler: Similar to the coil slitting machine, the uncoiler holds the large coil of material and provides tension as the coil is unwound. It ensures a consistent feed of material to the cutting process.

2. Straightening Unit: Depending on the material and its condition, a straightening unit may be included to remove any distortions or bends from the coil before cutting.

3. Feeding System: The feeding system moves the coil through the machine and positions it accurately for cutting.

4. Cutting Mechanism: The cutting mechanism is responsible for making precise cuts to the material. Different types of cutting mechanisms can be used, such as shear cutting, rotary cutting, or guillotine cutting, depending on the material type and thickness.

5. Measuring System: A measuring system ensures that the material is accurately positioned before each cut, allowing for consistent and precise cut lengths.

6. Stacker or Conveyor: Once the material is cut to the desired length, it is typically stacked or conveyed away from the machine for further processing or packaging.

7. Control System: Modern coil cut to length machines are equipped with advanced control systems that allow operators to set parameters such as cut lengths, cutting speed, and quantities.

Benefits of using a coil cut to length machine:

- Accuracy: These machines provide accurate and consistent cut lengths, ensuring uniformity in the processed material.

- Efficiency: Coil cut to length machines increase productivity by automating the cutting process and reducing manual labor.

- Waste Reduction: Precise cutting minimizes material waste, optimizing material usage.

- Customization: These machines allow for customization of cut lengths, meeting specific manufacturing requirements.

- Safety: Automation and safety features minimize the risk of accidents and injuries during the cutting process.

- Quality: The precision of the cutting process results in high-quality end products suitable for further processing or assembly.

Coil cut to length machines come in various sizes and configurations to accommodate different material types, thicknesses, and production volumes. When selecting a coil cut to length machine, factors such as the material specifications, cut length requirements, and production capacity should be considered. Proper training and maintenance are essential to ensure safe and efficient operation.