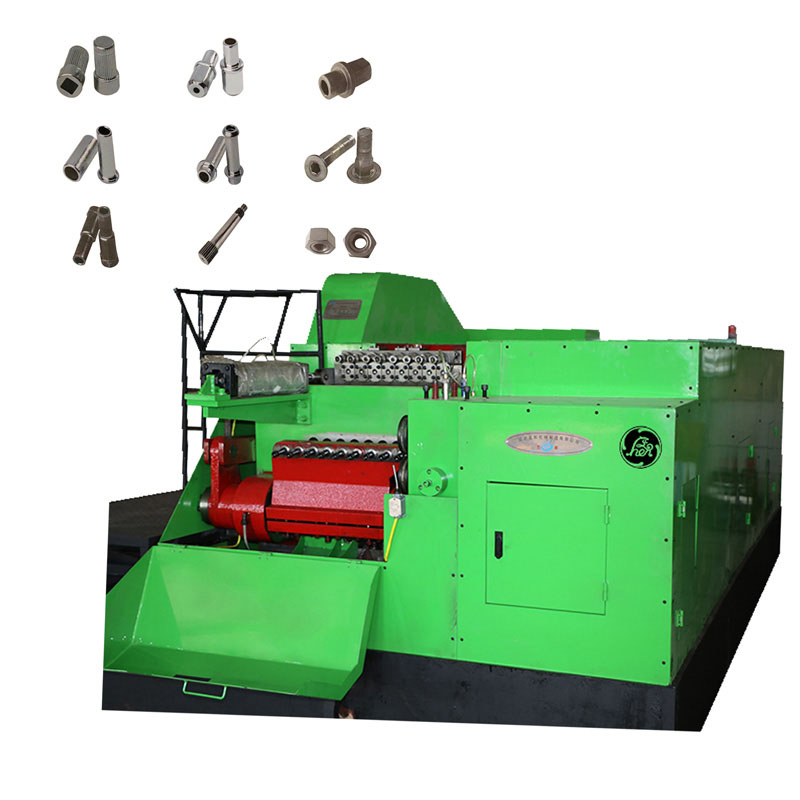

Chain Pin Nut Making Machine

A chain pin nut making machine is an industrial machine used for the production of chain pin nuts. Chain pin nuts are components used in various applications, including in the manufacturing of chains for conveyors, machinery, equipment, and other mechanical systems. These nuts typically have threade......

Send Inquiry

Product Description

A chain pin nut making machine is an industrial machine used for the production of chain pin nuts. Chain pin nuts are components used in various applications, including in the manufacturing of chains for conveyors, machinery, equipment, and other mechanical systems. These nuts typically have threaded holes that allow them to be attached to chains, connecting various parts of the chain links.

Function and Process:

A chain pin nut making machine is designed to automate the manufacturing process of chain pin nuts. The machine goes through a series of steps to transform raw materials into finished chain pin nuts. The process generally involves the following steps:

1. Raw Material Feeding: The machine takes in raw materials, which are often metal bars or wire, in the required dimensions and specifications.

2. Cutting: The raw material is cut into specific lengths, forming individual chain pin nut blanks.

3. Threading: The machine forms threads on the nuts to create the threaded holes. The threading process can vary based on the type of thread required and the specific design of the chain pin nuts.

4. Forming: The nuts are shaped according to the desired design and dimensions. This includes creating the body of the nut, forming any flanges or protrusions, and ensuring the overall shape conforms to the intended design.

5. Heat Treatment (Optional): Depending on the material and application, chain pin nuts might undergo a heat treatment process to enhance their strength and durability.

6. Surface Treatment (Optional): Surface treatments such as plating, coating, or other finishes might be applied to improve corrosion resistance and appearance.

7. Quality Control: Modern chain pin nut making machines often incorporate quality control mechanisms to ensure that the produced nuts meet the required standards for dimensions, threading accuracy, and overall quality.

8. Packaging: Finished chain pin nuts are typically packaged and prepared for distribution.

Machine Types:

There are various types of machines designed for different stages of the chain pin nut manufacturing process:

- Thread Rolling Machines: These machines specialize in creating threads on nuts and bolts. They can be used to create the threaded holes in chain pin nuts.

- Cold Heading Machines: These machines are used for cold forming and shaping of the nut bodies, including any flanges or other features.

Benefits:

Using a dedicated chain pin nut making machine offers several benefits, including:

- Efficiency: Automated processes improve production efficiency and reduce labor-intensive tasks.

- Precision: Machines can produce chain pin nuts with consistent dimensions and accurate threading.

- Customization: Machines can be adjusted to produce chain pin nuts of various sizes and thread specifications.

- Quality: Modern machines often include quality control features, ensuring high-quality finished products.

Considerations:

When considering a chain pin nut making machine, factors such as production volume, desired specifications for the chain pin nuts, machine capabilities, and maintenance requirements should be taken into account.